EPTATECH · Stretchable Electronics

EPTATECH · Stretchable Electronics

STRETCHABLE ELECTRONICS SOLUTION OVERVIEW

Stretchable Electronics Solutions Overview

The most distinctive feature of EPTATECH solution for stretchable electronics is the fact that it avoids the use of elastic membranes as base substrates for the printed circuits. EPTATECH conductive stretchable inks have been engineered to be used in combination with dedicated encapsulating inks with structural and mechanical features similar to those of TPU elastic membranes usually used as substrate in the industry.

The idea of encapsulating inks as an alternative to elastic substrates originated from the vast experience of the EPTANOVA Group in the so-called “transfer printing” technology commonly used in textile printing.

EPTAINKS, one of the EPTANOVA Business Brands, has in fact a broad and established portfolio of inks and materials for transfer printing for decorative purposes. EPTATECH further developed this initial idea and, thanks also to Client’s requests, has also formulated encapsulating inks that can be peeled of from sacrificial printing supports enabling further handling for assembly and connections (e.g. can be crimped).

Application Process

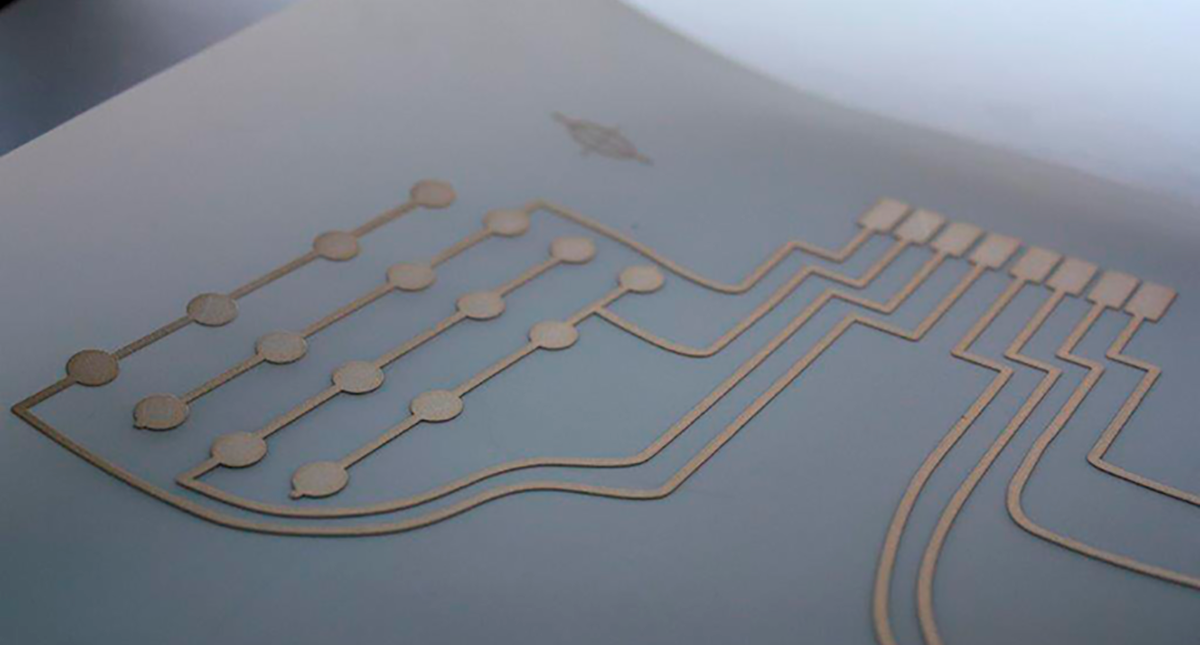

Encapsulating and conductive inks are screen-printed on a sacrificial support, typically a so-called “release” polyester film normally used in transfer printing. The printed artifacts are generally made of 2 outer layers of encapsulating inks, with open areas for any external connection, containing the “functional circuit” (e.g. a sensor) realized by a virtually unlimited number of layers of different inks.

By selecting the appropriate encapsulating ink a few options are possible for the final application:

- Textile applications (smart-garments, wearable technology type of applications). Transfer printing technology is used to transfer, by heat and pressure, the ink layer set from a sacrificial support to the final fabric. In this option printing operations are done in “reverse” mode with the last layer of ink being the closest to the fabric. The ink set is then overprinted with a thermoplastic adhesive.

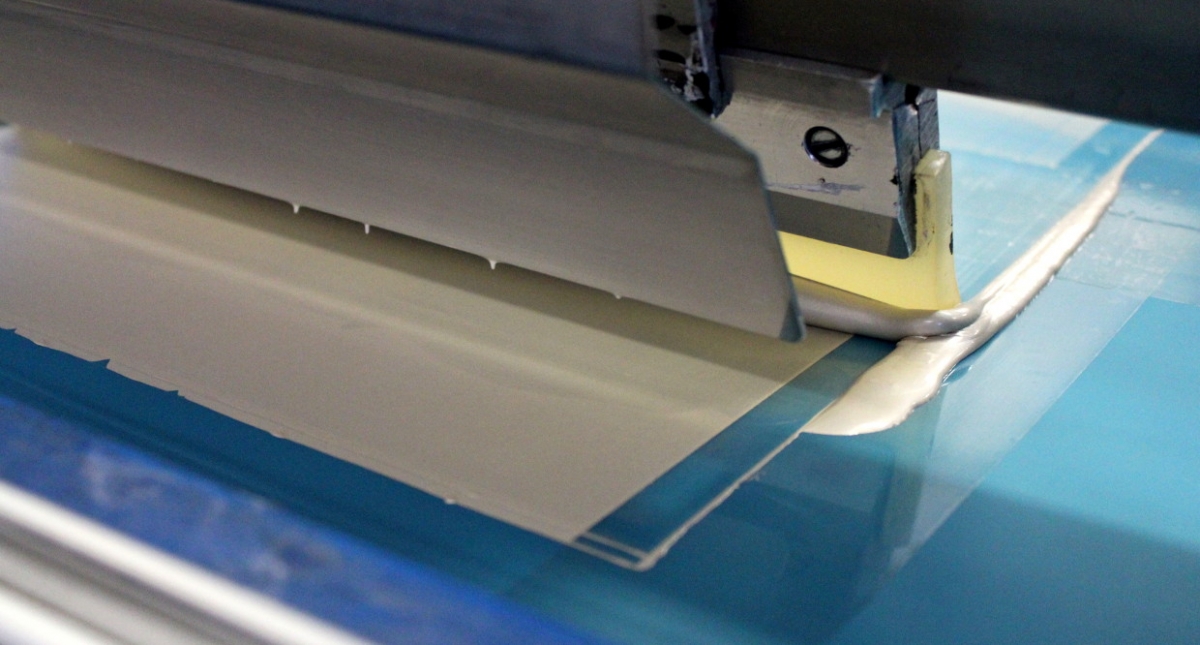

- Non Textile Applications. The printed artifact is directly peeled-off from the sacrificial support and its assembly on the final object can be done in different ways such as by using an adhesive or by crimping. Encapsulating inks standing severe industry environmental tests are also available.

At EPTATECH we believe this overall approach gives advantages in real life applications. Beside noting that “printing” a support is a far more flexible process than “extruding” it, opening-up opportunities for many variations, a few advantages are:

- Printing occurs on a (sacrificial) support that is dimensionally (flexible but not stretchable) and thermally stable allowing for a more reliable printing process especially when a few layers of inks are printed and dried sequentially.

- The production process is simplified because circuits are already actually printed in their final shape, avoiding any membrane cutting operations. Just the separation between sacrificial support and printed circuit is needed by peeling off one from the other

- No elastic membrane has to be permanently laminated on the fabric. Moreover the thickness of encapsulating ink can be fine-tuned as required by application (comfort vs robustness). In case of textile applications this ends-up in a better look and feel of the final garment.

Inks Portfolio

EPTATECH provides an assorted range of materials for “Stretchable Electronics” applications, such as:

- Conductive Inks

- Stretchable Silver based inks

- Stretchable Carbon based inks

- Encapsulating Inks

Encapsulating inks are used in synergy with conductive inks. Their functions are:- Structural support/mechanical stress absorption

- Primer in case of porous final surfaces (e.g. Textile)

- Barrier to water (for washing resistance)

- Electrical insulation

A choice of Encapsulating Inks is available depending on the final application. Customized encapsulating are also possible.

- Encapsulating Inks dedicated to Textile applications where final comfort is required

- “Peelable” Encapsulating Inks

- “Peelable” Encapsulating Inks for harsh environments

- Adhesive inks for Transfer Printing

All the Inks are:

- Water-based

- Screen printable

- Highly stretchable (tested up to 100% of elongation)

Electrical performances under strain

Currently, no standard test to evaluate the electrical performances of stretchable conductive inks is established. We usually perform single step-by-step elongations up to 100% stretch and 1000 cyclic 0-20% stretch elongations. By measuring resistance values and thickness of traces with simple geometries, sheet resistivity (the intrinsic electrical parameter) is calculated.

EPTATECH silver based conductive ink has an initial sheet resistivity below 30 mOhm/square@25micron. The graphs below show its typical resistance behavior under strain.

Figure 1. – Single stretch

Figure 2. – Continuous cycles

EPTATECH carbon based conductive ink has an initial sheet resistivity below 40 Ohm/square@25micron. The related electrical performance graphs are shown below.

Figure 3. – Single stretch

Figure 4. – Continuous cycles

According to our experience, many factors affect performances under strain:

- Encapsulating inks. The ones most resistant to washing exhibit a lower elasticity. This affects the overall electrical performance, especially under repeated strains

- Final fabric, in particular the weave more than the raw material

- Trace shape. Straight lines and corners are not the best performer

EPTATECH has developed base conductive inks and a few encapsulating inks which can be customized for the specific application.

Please contact us (info@eptatech.com) to evaluate ink performances against your requirements.

The Offering

Thanks to screen-building and printing facilities EPTATECH can support Clients during initial tests and feasibility studies by providing printed layer set (also based on Client’s design) ready to be either transferred or removed from the support and tested.

The inks are currently not available through EPTANOVA Dealer Network. This choice ensures a direct assistance to Clients in the fine-tuning of the printing processes, in the assessment of performances and in the evaluation of possible ink customizations.